-

Welcometo the Warrnambool Woollen Mill

Welcometo the Warrnambool Woollen Mill -

The Millpreserving and honouring its past and embracing an exciting future

The Millpreserving and honouring its past and embracing an exciting future -

The MillSurrounded by water

The MillSurrounded by water

Warrnambool Woollen Mill

Warrnambool, Victoria, AustraliaWelcome to the Warrnambool Woollen Mill website. Whether you are interested in the site as it continues to develop today, the history of the buildings, the environment around it or the people involved in its past, you will find it here. The community spirit is intact and some of its structures such as the old pump, the water tower, cellars and sandstone walls are also preserved.

A labour of love

A group of new community members (who have settled into homes on the old mill site) are passionate about the preservation of the stories contributed by the people who once worked there, as much as the preservation of the more physical surroundings. The history of the mill and its people can take its place in the broader history of Warrnambool. The introduction of signage in significant places around the mill is also planned.

This website contains links to information about workers and their stories, environmental changes around the site, research about war veterans who are remembered at the mill, photos, video, voice recordings and memorabilia that helps us understand how the mill operated. You will also find drone footage of how the mill has been developed and is still developing. It contains old and new photos, voice recorded interviews and old video footage.

This project has been a labour of love for all involved. We have attempted to reach as many of the people involved in the productive life of The Mill and thank those who have contributed so far. The strength and importance of community has been most apparent throughout our research. Our own knowledge has been expanded and our experience enriched as the community who take the site forward into the future.

The Warrnambool Woollen Mill at war

The Warrnambool Textiles War Memorial, on Harris Street, is an ornamental platform featuring an urn in the centre. The memorial was erected in honour of four residents who died overseas in the First World War and three who died whilst serving overseas in the Second World War.

Jeremiah Amor

Worked in lab making colour – worked with clients to decide colour – adjust after dying Tested textiles for quality after production Assist in dying production

Jeremiah Amor

Worked in lab making colour – worked with clients to decide colour – adjust after dying Tested textiles for quality after production Assist in dying production

Years Employed at The Mill: 1989 - 1992 (3 years)Relatives/Friends: Parents John & Virginia Amor & Sister Cherie Amor 12 – 20 people worked in dye house. Left because Mill going to Albury – Pat pulled him aside to tell him about a month before advising him to apply for jobs in Melbourne. Offered a job in Albury but took a job in Melbourne. Pleasant memories – drinks at Lady Bay Hotel. 19 YO when started –When hung over slept in wool stores (cellars) next to dye store. Pat very tolerant of discretions. April Fool’s Day – needed to be on toes all day – someone had to outdo last year’s pranks – glad wrap on toilet, tampering with lunch in fridge, fun with chemistry (a little dangerous) - crackles and sparks….involved in pranks Whistle reminded him he was late for work or late back from lunch. Chemicals from dye house released into river. No treatment plant. Highly acidic, highly caustic chemicals poured down drain - soda ash, caustic soda, acetic acid (vinegar), colour Would have stayed at Mill if kept going. Good with keeping equipment clean, wearing masks etc. If no mask you could be violently drunk and vomiting on ethanol – pure alcohol. Mill was first full time job allowing me to be independent. My favourite memories of working at the Mill were meeting people, sleeping on the wool bales when hungover from the Lady Bay or the Gallery the night before. Very sociable community at the Mill- Christmas Parties, drinks on special occasions and other friendly gatherings. I left the Mill in 1992 as I was advised by Pat (my boss) that I should look for more Dye House work in Melbourne as the Mill was starting to wind down. I always felt that the Mill was a great place to work.

Ted Bain

Winding

Ted Bain

Winding

Years Employed at The Mill: 1980 - 1986 (6 years) Relatives/Friends: Mother-Eileen Lane, Sister-Mary-Ellen Osborne, Brother-Gene Lane, Ian Chislett Shift work 7.00- 3.30 alternating with 3.30 till midnight. Mill shut down at Xmas for 4 weeks. Break up day after cleaning up your area you could be having a beer at 10.00am waiting for Timmy Dawson to arrive with holiday pay in cash. Very cold in winter and over 55 degrees inside in summer. Great Friendships.

Carol Boyd

Winding

Carol Boyd

Winding

My sister also worked at the Mill around the same time as me – Loran Haberfield (1963). One of the characters I remember is Frank Higgins – he always appeared grumpy, but was really a nice person. At the end of the shift we would have our area all cleaned up waiting for the whistle to blow – so we could leave for home. My least pleasant memories at the Mill were the noise and dust. I enjoyed the break up dinners at the Lady Bay Hotel I left the Mill to start a family in 1966.

Max Coomber

Assistant Foreman/Yarn Store Manager

Max Coomber

Assistant Foreman/Yarn Store Manager

Relatives/Friends: Father-Max Coomber, Mother-Gert Coomber, Brother-John Coomber, Grandmother-Ethal Hocking, Uncle-Clive Hocking, Great-uncle-Jim Watson

Good workmates. Lots of joking and fun. Closed the door on the last day. Received a gold watch for 25 yrs service. Staff gathered in the carpark. 2 weeks holidays at Xmas originally. Then 1 extra week in Sept. EventuallY 3 weeks at Xmas. Freezing in Winter Hot in Summer. Children’s Xmas party finished 1975. Gifts for all employees at Xmas. Whistle used as a timekeeper all over town.

Peter Goodman

Washed for Controlled Shrinkage/Dennis Jervis’s Leading Hand

Peter Goodman

Washed for Controlled Shrinkage/Dennis Jervis’s Leading Hand

Years Employed at The Mill: 1986/7 - 2000 (13/14 years) Relatives/Friends: Grandparents – Thomas & Margaret Goggin, Father – Stewart Goodman, Aunt – Heather Goodman My first job was working in the Cutting Room at Fletcher Jones & Staff. After returning from travels to WA I commenced work at the Mill working under the management of Dennis Jervis running all machines in the wet and dry departments. I washed for controlled shrinkage. I worked with the rollers and big spinner. The fabric came to us already dyed and woven. Later I became Dennis Jervis’s leading hand working on brushes, cutters, blowers and the dispatch of fabric. We made the rubber backing on the Billabong rugs. It was fun being at the factory but the work was boring at first. I waited two hours after putting the fabric in the mills which was monotonous. However it served its purpose as a fill-in job. I rode a bike to work. I made good friends, some of which I still have today.One spool was a couple of kilos, with sharp ends, called shuttles. They moved with great speed across the fabric. A shuttle could fly off a machine. I don’t remember the work so well but I remember the people. We played touch football at Lake Pertobe after hours and on weekends. Playing touch football was started by the New Zealand boys. Some women played. My father worked at the Mill in weaving. His father Thomas Goodman worked in cards. My aunty Heather Goodman worked there. Mum’s mother Margaret Goggin was in charge of the mending room. My father dragged a dead snake with fishing line through weaving room to scare everyone. We all had lockers with stickers. I peeled some off and saw I had my grandmother’s locker! John Sirikowski was an apprentice designer at a New Zealand Mill where Dad also worked then he also came to the Warrnambool Mill. I bought an old mending table from Mill. When the masonite top was taken off I found Mum’s Uncle’s name scratched into top. I really enjoyed working with the people at the Mill.

Robyn Harry

Spinning and Bobbins

Robyn Harry

Spinning and Bobbins

Years Employed at The Mill: 1980 - 1999 (19 years) Relatives/Friends: Willomena - Telephonist, Bill Allen - Supervisor, John Toohey – Cellars, Lyell – Office, Jerry Peoples – Paymaster, Joyce Hart – Secretary to Don, Eugene Tobin – Truck Driver Nobody was better than anyone else Everyone got on like a family Christmas parties at Lady Bay Hotel – great fun Boys from cards came over to spinning to tease girls Blood washed into river from tanning – river stank – people still fished Shared a bus from Port Fairy with Fletcher Jones girls – no love lost! Christmas shopping trips to Melbourne every year Majority of workers were good, down to earth people Could hear the whistle all around town – neighbourhood lived and worked by the whistle – blew 5 mins before shifts Factory worked around the clock – 3x8hr shifts – 11pm, 7am, 3pm Incredibly hot in Summer – heat off machines, no airflow A lot of girls got carpel tunnel We worked hard trying to outdo ourselves – more baskets out – bonus for quality of wool Family picnics Would do the same again – wonderful girls just like family.

John S Henderson

Wool Sorter (Dip Textile Design)

John S Henderson

Wool Sorter (Dip Textile Design)

Dennis Hughson

Production Control

Dennis Hughson

Production Control

Years Employed at The Mill: 1969 - 1999 (30 years) Relatives/Friends: Jedda Walsh – Knew Everybody, was very funny and would talk all day, Alan Ryan, Dan Carey, Ray Hawthorn still good friends Chose to work at Mill as it was only 5 minutes away – very convenient, could walk. Was a Shop Steward in Clerks union and Textile union Started on $49/week and ended on around $400/week. Enjoyed nights out with co-workers. Football game organised one year between the Mill and Fletcher Jones. Was retrenched when Mill was on the verge of closing. Received a gold watch for 25 years service. Met a lot of people, created many friends. Great place to work for. Things changed when Mill got sold off. 400-500 worked there in beginning. Worked for Smith family, Dunlop, McQuarie Mills.

Mary Jackson

Mending Dept

Mary Jackson

Mending Dept

Relatives/Friends: Kitty Johnson (Mother)

I was born in Shetland, Scotland. When my mother Kitty was pregnant with me she contracted German Measles and I was born profoundly deaf. I spent 9 years attending a boarding school for the deaf in Aberdeen and learnt to speak and lip read. We moved to Australia and I spent a further 13 months attending a school in Melbourne for the deaf. My mother Kitty was instrumental in me getting my first job (at the age of 16yo) at the Mill. I was very nervous to work with hearing people as I felt my speech wasn’t great but I was made to feel very welcome and made great lifelong friends. During the time I worked at the Mill I lived at 1 MacDonald Street (my father Archie Johnson built this house). My mother Kitty and I would walk across the footbridge and we would go home for lunch as we lived so close to the mill. In 1963 I married Joseph Jackson who was a plumber that worked with my father (carpenter). Between 1963 and 1975 we started a family and had three children. In 1976 I returned to the Mill to work a further four years. Living so close to the mill I remember the Mill Whistle. We didn’t have to use any alarm clocks as we always knew the time by the whistle. It is so sad to see the Woollen Mill no longer there – life was great in those days with plenty of work for all.

Don Jenkins

Office Boy (various sections) - Production Control & Managing Director 1971-1989

Don Jenkins

Office Boy (various sections) - Production Control & Managing Director 1971-1989

Years Employed at The Mill: 1934 - 1 989 (54 years) Don wasn’t happy being under control of Onkaparinga. December 1982 General Investments took over Onkaparinga. Not so much competition. Started with black coal from Newcastle. Boat pulled up at breakwater and onto train to Mill site 1909 – 1939. Changed to brown coal from somewhere near Winchelsea and came from train. Always had own generator for electricity. Supplied power for lights in South Warrnambool. Then briquettes, oil, then gas. 2 hot water boars at the Mill, one near boiler room, one in wool processing department. Didn’t know it was hot. Don used water- divining to find them. Mills transferred to Warrnambool - Machinery bought, Wendouree Ballarat, Ballarat woollens and Worsteds, Morris Mills Qld, Laconia South Melbourne, Many in Geelong, Target Mills Sydney, Invicta Essendon. Dreamspun from Brunswick – whole Mill bought 1979. ***more on audio First in world to use Sulzer machines from Switzerland for weaving – big gamble. Whistle run by steam from the boilers – firemen pulled cord. Everyone set their clocks by whistle. Initially whistle blew at 7:00 (time to come to work), 7:25, 7:30 (start), 12:00 (lunch), 12:40 (get ready to go back), 12:45, 5:00 (knock off). Changed over years – 2 shifts for years then a triple shift – only for extra production. Sometimes river flooded. Water came into lower parts of Mill. Water storage in cellars. Mill built a weir near bridge (sand bags) to stop salt water coming up river. River water chemically treated then pumped up to water tower on top of cliff. Then gravity fed to departments needing water. It made steam and was used for washing and finished in septic tanks then to sewerage. 144 ft high chimney. Firemen went to sleep and burnt bum out of boiler when using briquettes. Down to one boiler. Used wood during war years (1940-44) 400 tons/week. Then back to briquettes. Most people walked over bridge from Sth.Warrnambool or rode bikes. Manager drove a car. Women never put into ‘dirty’ work. Originally women and men got different rates of pays, but changed over time. Men provided with boots. 2 weeks holiday over Christmas when Mill closed down and 2 weeks more. Christmas Party on wool bales with tables. Everyone got a present – playing cards, coasters, biscuits. Most got a large Christmas bonus – pay for the unused sick leave. Introduced profit sharing for employees. Profit made EVERY year! Workplace injuries – bad backs, 2 deaths (one not work related, one in a 3 m fall) fingers caught in moving machinery. Shift in level of water in the Breakwater – water used to rush through into where car park is now. Only thing left after abattoirs was pump house (taking water to tanks) when new Mill built. Another tank for emergency sprinkler system. Some tanks in ground on top of hill. Don sent overseas regularly to study new machinery. CEO of Ballarat, Scotland and China Mills. Dunlop bought Mill in 1968. Installation of new machines to replace 100 picks/min to 600 picks/min. No one else could compete. Made a difference to production and profit. Don told to get new world-class machinery at any cost. Made blankets for prisons and Defence Force. Electric blankets were first under blankets 1958 (Overseas ones were over-blankets) Still in use! Guaranteed for 20 years. Greeks and Cypriots at Dreamspun in Brunswick wanted separate amenities so Don shifted factory to Warrnambool $500,000. War years – Blankets and material for great coats made and tartan for Scottish Regiments. Part-time cost accountant at Fletcher Jones when it began as well as at the Mill. CHALLENGING TIMES BUT GOOD TIMES!

Environs

Much of what the 1st European settlers saw when the town of Warrnambool first began in 1847, still remains today. In those times it was noted it was “thick bush…, sand hummocks and swamp”(Yule & Sayers P4) Today, remnants of bush still abound in coastal areas, sand-hummocks still line our beaches, protecting land from the sea, and swamps still lie within the South Warrnambool area at Salt Marsh and beyond, plus there’s what has become our beautiful Lake Pertobe, alive with birdlife and frogs.

0

Number of Employees 1940’s

0

Years of Operation

0

Employees that went to War

0

Employees that lost their lives at War

-

Building 11

Buildings

-

The Mill Today 4

The Mill Today

-

Building 4

Buildings

-

Administration 3

Administration

-

Employees 5

Employees

-

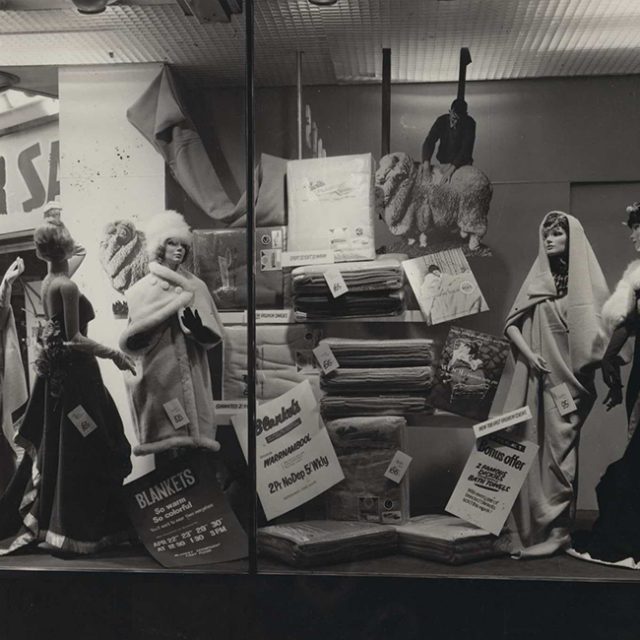

Blankets 3

Blankets

-

Equipment 8

Equipment

-

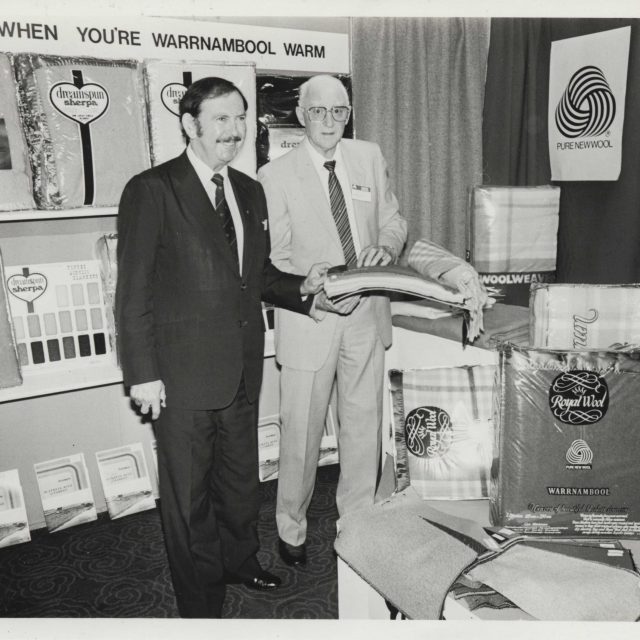

Showroom 2

Showroom

-

Showroom

Showroom

-

The Mill Today 2

The Mill Today

-

Administration 1

Administration

-

Showroom 3

Showroom

-

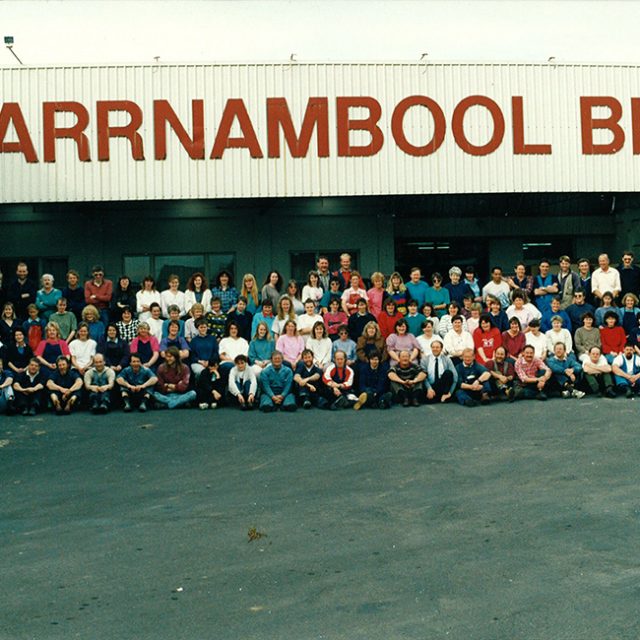

Employees 3

Employees

-

Equipment 2

Equipment

-

Blankets 2

Blankets

-

Blankets

Blankets

-

Sporting Teams 22

Sporting Teams

-

Buildings 3

Buildings

-

Equipment 4

Equipment

-

Equipment 5

Equipment

-

Buildings 12

Buildings

-

Employees 4

Employees

-

Employees 6

Employees

-

Equipment 3

Equipment

-

Buildings 6

Buildings

-

Employees 1

Employees

-

Equipment 9

Equipment

-

Building 9

Buildings

-

Buildings 5

Buildings

-

Sporting Teams

Sporting Teams

-

The Mill Today

The Mill Today

-

The Mill Today 5

The Mill Today

-

Employees 7

Employees

-

The Mill Today 8

The Mill Today

-

Equipment 7

Equipment

-

Administration 2

Administration

-

The Mill Today 7

The Mill Today

-

Equipment 6

Equipment

-

Employees 10

Employees

-

Buildings 2

Buildings

-

Showroom 3

Showroom

-

Buildings 1

Buildings

-

Building 8

Buildings

-

Equipment

Equipment

-

The Mill Today 3

The Mill Today

-

Employees 2

Employees

-

Buildings 10

Buildings

-

Employees 9

Employees

-

Building 7

Buildings

-

Employees 8

Employees

-

Blankets 1

Blankets

-

The Mill Today 6

The Mill Today

The Mill

by Anne Sims